Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

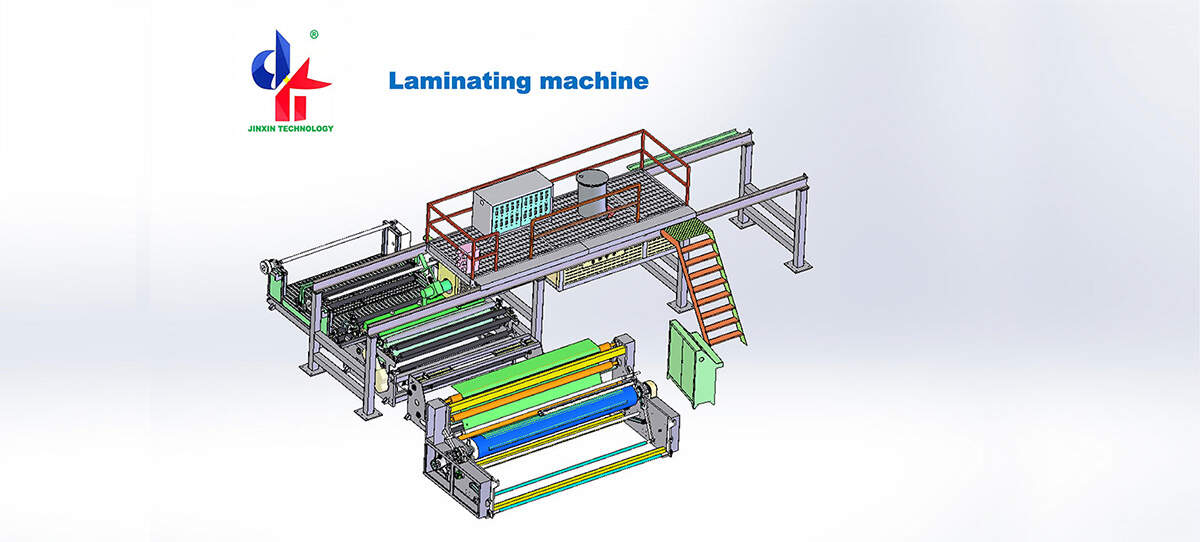

China Supplier BOPP Thermal Film Lamination Machine PP PE Extrusion Laminating Machine for Paper/ Fabric /Aluminum Foil

Delta PLC manages our automatic thermal film laminating machine. One individual can manage well. This highly automated machinery can speed up the process and increase effectiveness. Heat transfer oil is used to warm the steel roller, which is then heated in a circle by the mold temperature machine.

Film separation and punching equipment are included with this laminating machine. installed sheet drawing control (Pull gauge).

| Model | JX-laminating machine | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 12*10*3.5m | 12*12*3.5m | 12*16*4.5m |

| Mechanical Speed | 200m/min | 200m/min | 150m/min |

| Thickness | 0.01~0.1 mm | 0.01~0.1 mm | 0.01~0.1 mm |

| Daily Output | 2-3T/Day | 3-4.5T/Day | 4-5.5T/Day |

| Transformer Capacity | ≈80KVA | ≈120KVA | ≈180KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Brief introduction

Our automatic thermal film Laminating Machine is controlled by Delta PLC. One person operates easily. This Highly automated equipment can shorten the time of procedure and enhance efficiency. The steel roller is heated by heat transfer oil, and circularly heated by the mold temperature machine.

This laminating machine is equipped with film separating and punching devices. With sheet drawing control installed (Pull gauge).

Machine features

High-speed feeder

China's best brand, with a double sheets detector.

Laminating unit

This machine is equipped with film separating and punching devices. Paper overlap adopts servo technology, precision is high.

Sheets Separating unit

The laminated products passed the punching devices and were separated easily. There are pressing rollers and pulling rollers to separate sheets.

Separating unit adopts pneumatic device, it is automatic, operated easily.

Product applications

It is used for the lamination of pre-glued film, paper, fabric and aluminum foil.

About us

We are China's leading manufacturer of film laminating machines. We manufacture & supplying the commercial print industry with an extensive range of robustly manufactured laminating machines to enhance and protect the print.

Our highly skilled engineers take pride in producing top-of-the-line machinery that is world-renowned for its quality, reliability, and productivity.

We manufacture in Fujian, China, and our machinery is built by skilled engineers. We utilize top-quality components. This quality in manufacturing allows our customers to produce a higher quality print with a greater perceived value. Our machinery is designed to with very little downtime or regular maintenance requirements, saving our customers invaluable time and financial resources.

We manufacture machinery with exceptional productivity, which often reduces labor costs and provides a very quick return on investment.